IATF 16949

IATF16949 automotive quality management system standard is the basic requirement of the common and only automotive industry quality management system in the world, which has replaced the original technical specifications of the automotive industry in various countries (such as: QS-9000, AVSQ, VDA6.1 and EAQF, etc.). The standard was developed by the International Automotive Task Force (IATF) and supported by the International Organization for Standardization Technical Committee on Quality Management and Quality Assurance (ISO/TC176).

The IATF16949 standard, together with the applicable automotive customer-specific requirements and the requirements of the ISO9001 standard, defines the basic quality management system requirements for organizations of automotive production and related service parts. Because IATF16949 standards are closely related to the main and key businesses of the automotive manufacturing industry, many automotive manufacturers (OEMs) and suppliers have made IATF16949 standard a mandatory requirement. Establishing a quality management system that meets the requirements of IATF16949 standard and obtaining third-party certification through this standard has become one of the key factors for manufacturing enterprises to enter the automotive production field or the entire vehicle supply chain.

(1) Improve product and process quality;

(2) Enhance confidence in global procurement;

(3) Reallocate supplier resources for quality improvement;

(4) Provide suppliers with a universal quality system methodology;

(5) Reduce multiple third-party certifications.

(1) Organizations within the entire automotive supply chain;

(2) The manufacturing sites requested by customers for production and/or service parts;

(3) For support functions, whether on-site or remote (such as design centers, group headquarters, and distribution centers), they are a necessary part of the on-site audit as they support manufacturing site. The support function cannot be certified against IATF16949 alone.

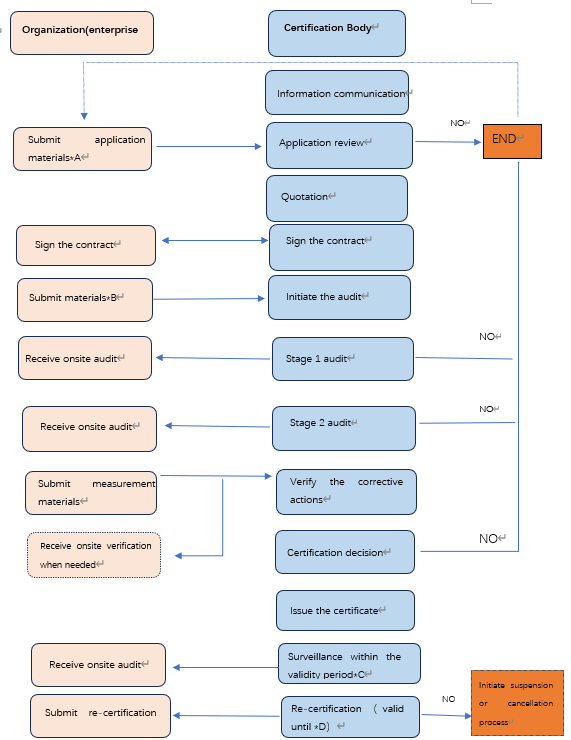

IATF 16949 certification service: Enterprises submit certification applications (CASC's "Certification Application Form"). After the contract is signed, CEPREI will arrange auditors to conduct a stage-based audit. After passing the audit, the IATF16949 certificate will be issued.

Note 1: The interval of surveillance is 9-13 months, with at least one surveillance per year.

Note 2: The certificate is valid for 3 years.

*A:see ”Certification application” of CASC and the attachment material requirements in it.

*B: see “Preparatory review table ” of CASC and the attachment material requirements in it..

*C: the interval of surveillance is usually 9-13 month; at least one surveillance each year.

*D:the certificate is valid for 3 years.

Since obtaining authorization from the three major American automotive companies to conduct QS9000 certification in 1998, CPEREI has accumulated over 20 years of experience in the automotive industry, with rich experience in automative research and development management and quality management. For many years, CEPREI has been committed to technical research in quality management of the automotive electronics and automotive software industries. It has operated multiple certification services, including TS/IATF16949 certification, Automotive SPICE assessment, ISO26262 certification, TMMi assessment, ISO/SAE 21434 certification, ISO24089 certification, ISO 21448 certification, and so on.

CEPREI has a highly qualified professional technical team which can provide customers with high-quality services. At present, there are more than 50 technical service personnel in the automotive area. The various assessors and certification personnel of CEPREI are personnel with more than ten years of work experience in enterprises, and have rich experience in automotive electronics and software development.

- IATF 16949 Enterprise Application Form for surveillance2024-12-04下载